Release Time: 2025-11-11

Supercritical Foam Material for Shoe Midsoles refers to a specialized foam material produced through supercritical fluid technology, primarily used in the manufacturing of shoe midsoles. Supercritical fluids are substances that are in a state where the liquid and gas phases merge under specific pressure and temperature conditions, resulting in unique physical properties. By utilizing this technology, supercritical foam materials achieve outstanding cushioning, comfort, and durability in high-performance, low-density foam structures.

Compared to traditional midsole materials, supercritical foam offers a lighter weight, greater elasticity, and superior impact resistance. The use of supercritical CO2 (or other gases) in high-pressure conditions creates a uniformly distributed bubble structure within the material, resulting in excellent shock absorption and reducing the impact force on the feet during movement. Additionally, these materials provide better breathability and temperature control, keeping the wearer dry and comfortable during physical activities.

Market Status and Trends:

As consumer demand for high-performance and comfortable footwear increases, supercritical foam materials are gaining popularity in the footwear industry. They are increasingly used in high-performance sports shoes, such as running and basketball shoes, for their superior cushioning and shock absorption. Market research indicates that the demand for supercritical foam materials in the footwear industry is expected to continue growing between 2025 and 2030.

Moreover, environmental factors play a significant role in driving the development of this material. The production of supercritical foam often uses non-toxic and harmless CO2 as a foaming agent, reducing harmful emissions compared to traditional chemical foaming agents. This aligns with the global trend toward sustainability and eco-friendly practices, making supercritical foam an attractive option in the environmentally-conscious footwear market.

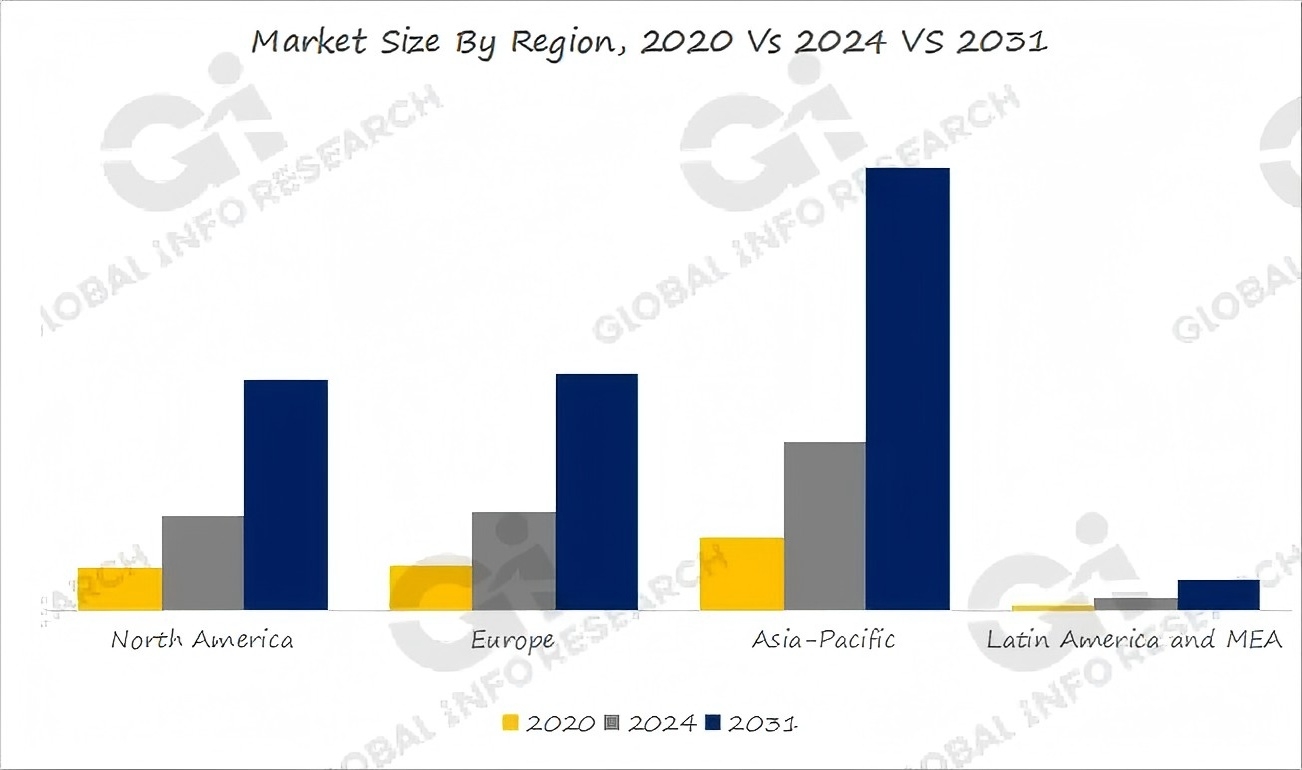

The global footwear industry is increasingly adopting this innovative material, and as production technologies advance and costs decrease, supercritical foam is expected to capture a larger market share in the coming years. This trend is particularly prominent in the Asian and North American markets, where consumer demand for high-performance, eco-friendly shoes is on the rise.

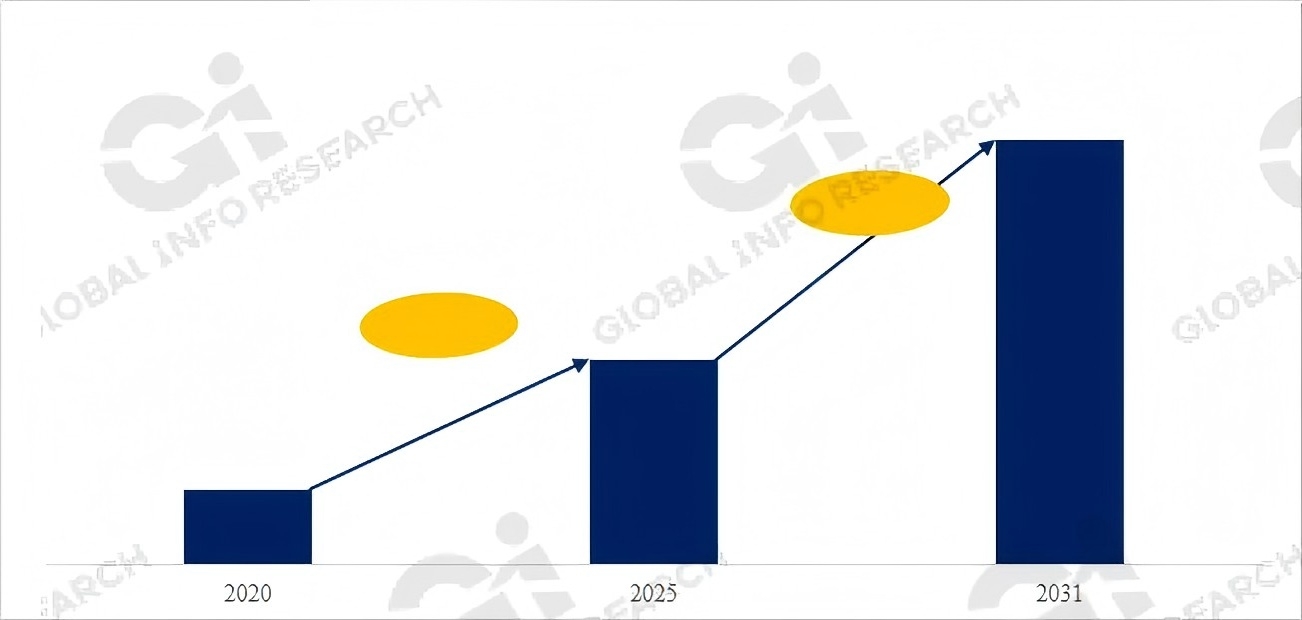

According to the new market research report “Global Supercritical Foam Material for Shoe Midsoles Market 2025 by Manufacturers, Regions, Type and Application, Forecast to 2031”, published by Global Info Research, the global Supercritical Foam Material for Shoe Midsoles market size is projected to reach USD 0.26 billion by 2031, at a CAGR of 12.5% during the forecast period.

Figure1. Global Supercritical Foam Material for Shoe Midsoles Market Size (US$ Million), 2020-2031

According to Global Info Research Top Players Research Center, the global key manufacturers of Supercritical Foam Material for Shoe Midsoles include BASF, Zotefoams, Shincell New Material, Xinrui New Materials Technology, Hairuisi New Materials, etc. In 2024, the global top five players had a share approximately 68.0% in terms of revenue.

Figure2. Global Supercritical Foam Material for Shoe Midsoles Top 9 Players Ranking and Market Share (Ranking is based on the revenue of 2024, continually updated)

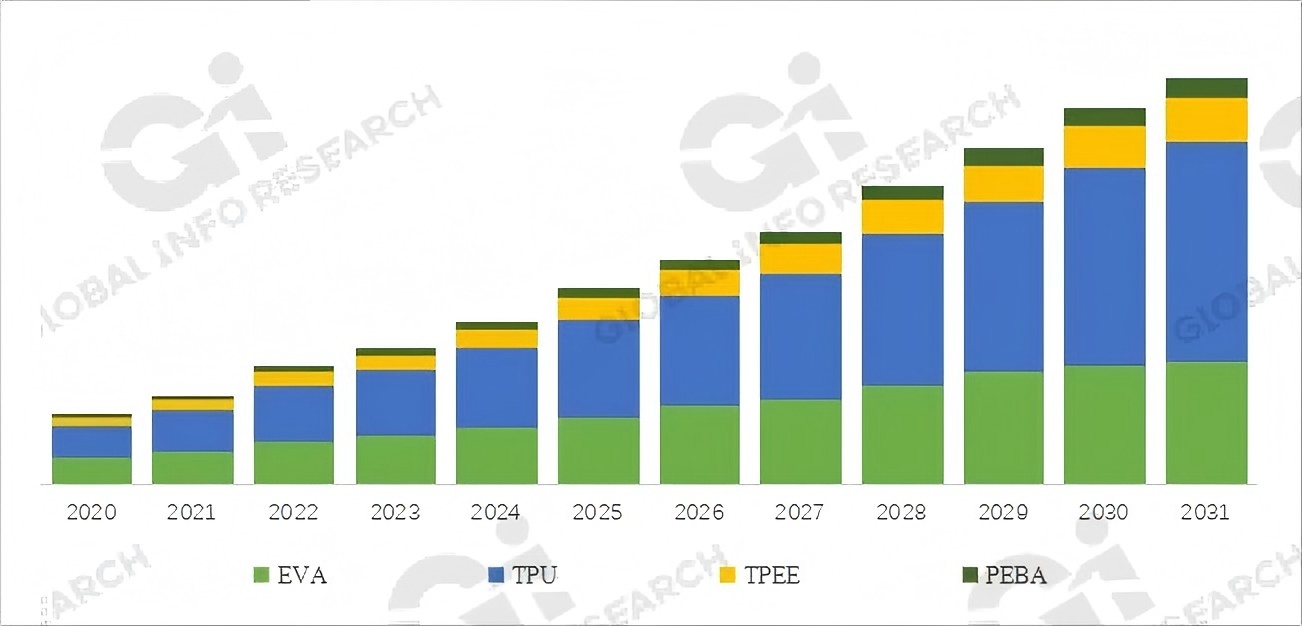

In terms of product type, currently EVA is the largest segment, hold a share of 35.4%.

Figure3. Supercritical Foam Material for Shoe Midsoles, Global Market Size, Split by Product Segment

In terms of product application, currently Running Shoes is the largest segment, hold a share of 98.9%.

Figure4. Supercritical Foam Material for Shoe Midsoles, Global Market Size, Split by Application Segment

Figure5. Supercritical Foam Material for Shoe Midsoles, Global Market Size, Split by Region

The subject content of the Supercritical Foam Material for Shoe Midsoles report research consists of 5 chapters:

Chapter 1, to describe Supercritical Foam Material for Shoe Midsoles product scope, market overview, market estimation caveats and base year.

Chapter 2, to profile the top players of Supercritical Foam Material for Shoe Midsoles, with revenue, gross margin, and global market share of Supercritical Foam Material for Shoe Midsoles from 2019 to 2024.

Chapter 3, the Supercritical Foam Material for Shoe Midsoles competitive situation, revenue, and global market share of top players are analyzed emphatically by landscape contrast.

Chapter 4 and 5, to segment the market size by Type and by Application, with consumption value and growth rate by Type, by Application, from 2019 to 2030.

For more information, please refer to "Global Supercritical Foam Material for Shoe Midsoles Market 2025 by Manufacturers, Regions, Type and Application, Forecast to 2031". This report analyzes the supply and demand situation, development status, and changes in the industry, focusing on the development status of the industry, how to face the development challenges of the industry, industry development suggestions, industry competitiveness, and industry investment analysis and trend forecasts. The report also summarizes the overall development dynamics of the industry, including the impact of the latest US tariffs on the global supply chain, the supply relationship analysis of the industrial chain, and provides reference suggestions and specific solutions for the industry in terms of products.